Electroforming Tool

Electroforming Tool- Ultrafine esthetics

-

Electroformed Nickel Molds of Moltex

Investigation of extreme grain expression led Moltex to build special

molds for soft-skin processes. With strong demands for emotional

textures, technological advancement has enabled soft-skin processes

to be in a premium position in automotive interiors. Soft-skin

processes include powder slush molding (PSM) and in-mold graining,

but nickel molds are also widely applicable in injection and

PU-forming processes. These processes enjoys ultra-fine structure

of grain surfaces by utilizing the superior physical properties

of nickel mold. -

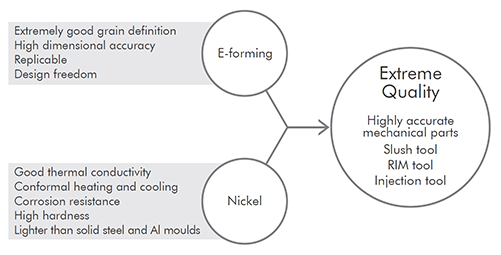

Principles

Electroforming and electroplating are synonyms for the method of nickel deposition. This bottom-up process takes advantage of atom-by-atom deposition on master subject, verifying extreme details of grain features. Once master is built and kept in the form of hard resin standard, the surface with accurate dimensions can be replicated as many as required during almost permanent term. Usually nickel layer in a mold has 3~5 mm thickness, and often called “nickel shell”. Thickness control is important to provide mold with proper thermal properties and physical strength.

-

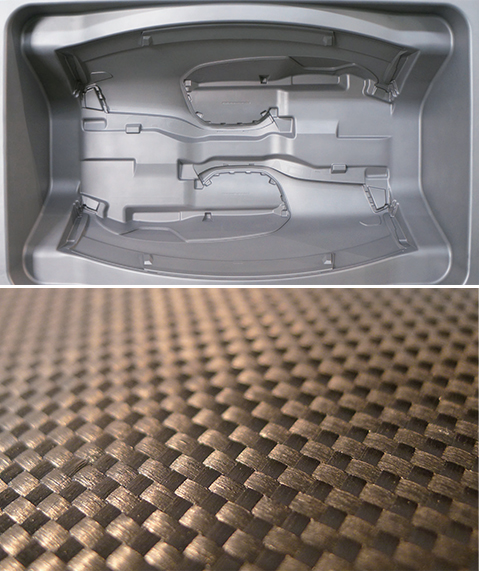

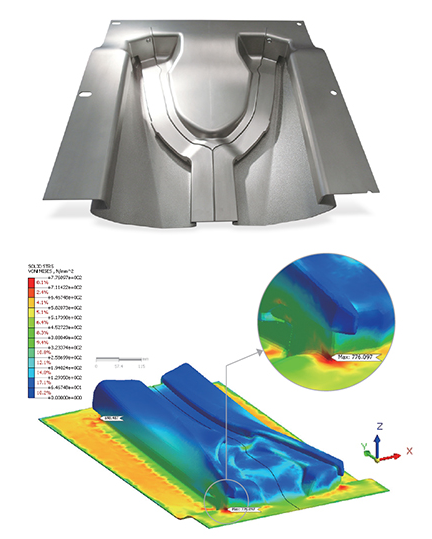

Slush Molds

Moltex slush molds have gone through year-by-year

evolution and are now widely applied with a variety of

demands from industry. For whatever type of slush process

machine, Moltex slush molds perfectly function to meet its

requirement by vigorous customization. Our research on

schematic thermal process in a particular system is truly

important to deal with extension of mold lifetime in an effort to

shorten process cycle time defined by the system.

Structural correlation and feasibility for PU-forming are

also studied to offer optimized process condition to

customers. -

Vacuum Forming Molds

Direct transfer of grain details from mold to skin is the most

attractive characteristics in processes that use electroformed

nickel mold. IMG (in-mold graining, female of negative type)

is one of them. IMG gets now more popular than ever, due to

the extremely accurate feature of grain quality, free from

positional depth loss or distortion which are often observed in

male-type vacuum process.

Tiny pores throughout nickel shell cavity are specially

manutactured by in-situ methodology which is driven by Moltex’

core technology. perfect control of pore size/shape,

location, and density in one-pot process is the most important.

-

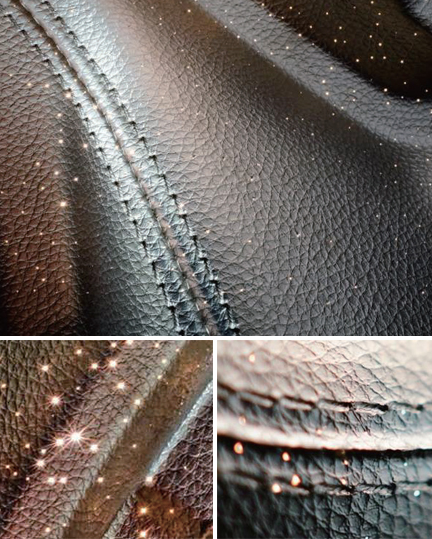

Stitch Application

Upon frequent designer’s requirement special, decorative features are implanted in mold. Stitch is the most exemplary. Moltex realize stitch

features very naturally, and customers don’t need to suffer from high

cost and fluctuating reliability arising from manual jobs of sewing.

You can enjoy artificial stitching lines both in slush and IMG molds

that may look better than natural. Moreover, combination of artificial

and traditional real stitching gives more opportunities and flexibilities

to customers with respect to the relationship of manufacturing cost and product quality. -

Total Service Available

To provide total service from mold design to test trial, Moltex team is equipped with entire facility to enable ureol or metallic master models, leather wrapping (Pretex®), resin models, electroforming, mold assembly, and test trial shots. There are 20 full size electroforming tanks which are adapted for large items (instrument panels), and the capacity is ready to meet their yearly production plan. Pilot systems for vacuum forming process enables fine-tuning of molding conditions, and facilitate mass production in supplier’s place.

-

New Process Research

Broad applications of electroformed nickel mold are studied more actively than ever. Skin preforming by female process can be used for direct back-injection, one-step lamination followed by automated trimming. On the other hand, direct PU-forming without preformed skin is also a possibility. TPO injection using nickel mold presents high quality injected parts. All these stories are commonly oriented to nickel shell that expresses ultimate art of surface textures, and should definitely offer the variation of process applications. Moltex is the pioneer in new technology development in this regard.