Chemical Etching

Chemical Etching- Traditional way

but distinct class

-

Chemical Etching - Art on Plastics

Chemical etching is traditional, but still the most versatile treatment

to express texture details on steel surface.

For this reason, Moltex etching technology is popularly applied in

many plastic industries. Whatever application your product

requires, our textures by etching provides beautiful and natural results

that certainly elevate your product values. A variety of textures collected

not only mimics natural appearances often seen in leather and fab-

rics, but also presents countless creative arts. -

Always the Right Art

At Moltex, you will get immediately inspired by a huge number

of ready-made texture designs and simply choose what you need.

You can also ask customization upon your ideas, and designers

and engineers in Moltex make efforts to implant exact design

flavor on your product through intensive discussions with you.

-

Handcraft but Cutting - Edge Technology

Manual skill is very important, and more than a hundred

qualified engineers, technicians, and artists struggle towards the

uniqueness of designs everyday. More importantly, however,

various high technologies and scientific knowledge are

integrated for the work. Chemistry always drives work conditions

to optimize in film printing, masking agent, and etchant blending.

Our simulation analysis renders textures to be previewed and

significantly eliminates potential mistakes during the manual job.

-

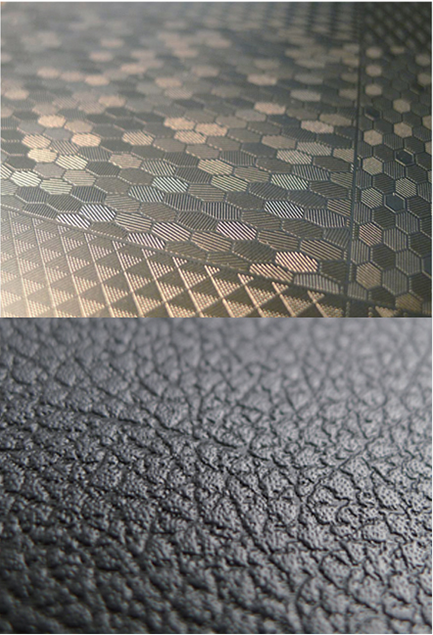

Multi-Layer Photochemical Etching

With Moltex, you are benefited from decades of experience in 3D

patterning, which is Multi-Layer Process. Chemical etching process

is natively 2-dimensional and obviously limits design freedom in

the expression of complicated nature of texture surface. Minute slices

along with surface level are handled by multi-layer etching

process to break through the restriction. -

Single-Layer Etching (SingLet®)

Thanks to advancement of DPS, single-layer etching that astonish-

ingly expresses 3D patterns is available now. Instead of slicing

embossed surface to obtain a number of contour layers, an image

in depth-proportional grey-scale can be used as film. It is a great

contrast with traditional multi-layer process, giving you fairly neat

quality of textures. SingLet® is simple, easy, and fast enough to

meet customer’s cost effective requirement. Just select a way of

texturing that makes you work easier from our comprehensive

range of artwork. -

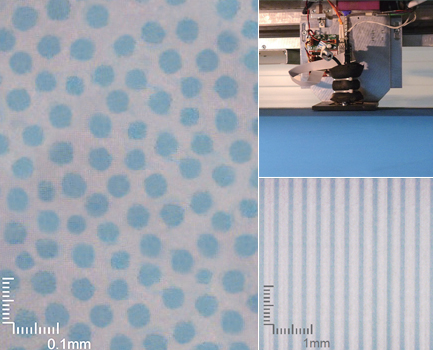

Digital Printing System (DPS)

Moltex challenges the real limit of details day-by-day. Now a

few-decamicron scale of dots and lines are available thanks to the

DPS. This system enables higher resolution of textures on films

and ultimately on plastic surfaces. Human naked eyes marginally

discriminate the limit and the system delivers finer textures than

ever. Digital control also guarantees uniform quality throughout

surfaces. -

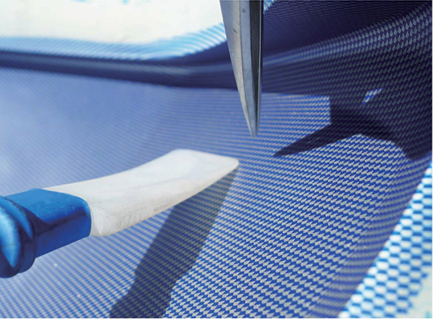

Dual-Tone Graining

Dual-tone graining is another powerful application of Micro-Texture

Treatment (MTT®).

Handling light reflection on surfaces, we can create a lot of

fantastic visual effects. Dual-tone grains are often recognized due

to its distinct line contrast in patterns originated from the separate

gloss features between the top and bottom surfaces of embossed

grain. This sophisticated gloss manipulation is only enabled by

such a high resolution printing technique.

-

Gloss Control is No More an Option

Customers enjoys a variety of techniques that control gloss level

on a pre-textured mold surface. Flatex® is the first generation

process to deal with gloss, and now more fine-tuned treatment is

implanted in conjunction with DPS. Micro-Texture Treatment

(MTT®) is reborn as present generation of technology.

Surface modification to scatter light reflection is adjusted by fine

lines and dots realized at up to 2500 dpi.